I. AMADA BENDING MACHINE USER MANUAL

Advantages of the Amada bending machine

- Automatic operation mechanism: the execution engineer only needs to put the metal workpiece in the right position according to the angles and points that have been slotted V, then adjust and perform the stamping process quickly and safely to shape the product according to his wishes without spending too much effort like other manual methods.

- Fast machine speed: With the operating capacity of up to thousands of degrees Celsius, the machine has a fast stamping speed, accompanied by great stability and stability, performed for many hours without worrying about fire. That is why factories invest in high-tech stamping machines to shorten production time, do not take much labor but still give great work efficiency.

=> A better understanding of how to operate the machine CHẤN AMADA access the following video link: https://youtu.be/B2Qd4ZvDjOM

Amada dammowers have fast, accurate cutting speed with large capacity

- Precision stamping: for high precision even the most difficult part is the angle of shock. Along with that, thanks to the professional skills and experience of engineers skillfully adjusted to create the finished product.

- Bulk shock: With just a few operations with CNC doughnuts, you immediately have a large number of parts needed for the next stages, many times faster than making with other machines.

- Strong shock force: up to 200 tons with a seismic length of 4000 mm, giving you fast, strong, decisive operation, ensuring not to lose corners of details, creating artistic features for the machine.

- Processing on many materials: depending on the requirements and product characteristics and the manufacturer selects the material accordingly. From iron, steel, cast iron are materials with high hardness or stainless steel, shock processing can be done. This is something that few products do.

Disadvantages of traumatic machining technology

In addition to many undeniable positive benefits, the trauma machining method also has a few disadvantages that need to be overcome. Above all, the product always requires high precision, especially in the corner, requiring the performer to have the expertise and experience to control the flexible workpiece to produce a completely accurate stamping line. Stamping is also costly to mold, V groove etching and mold maintenance depending on the complexity of the part.

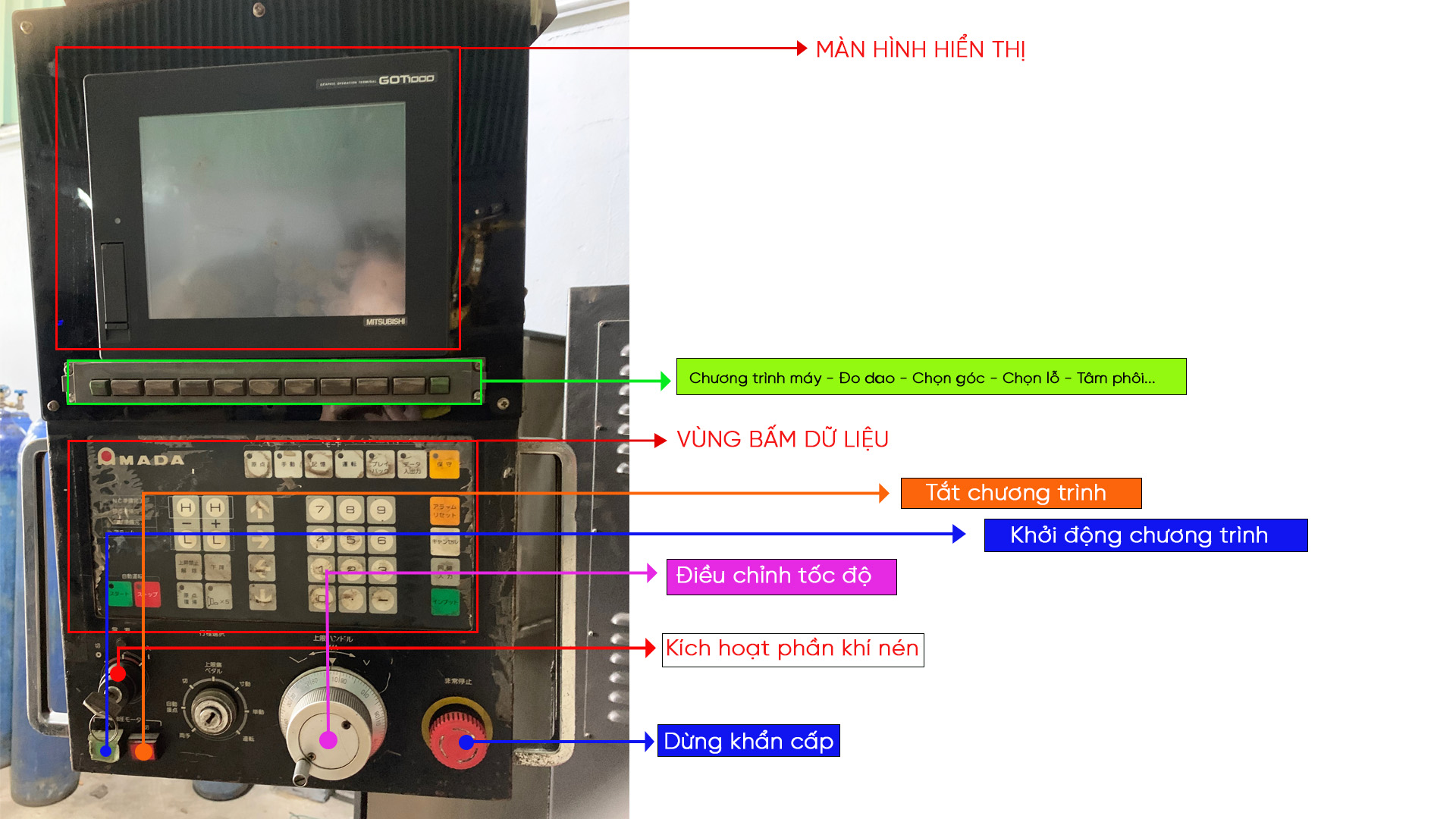

- Machine operated wing

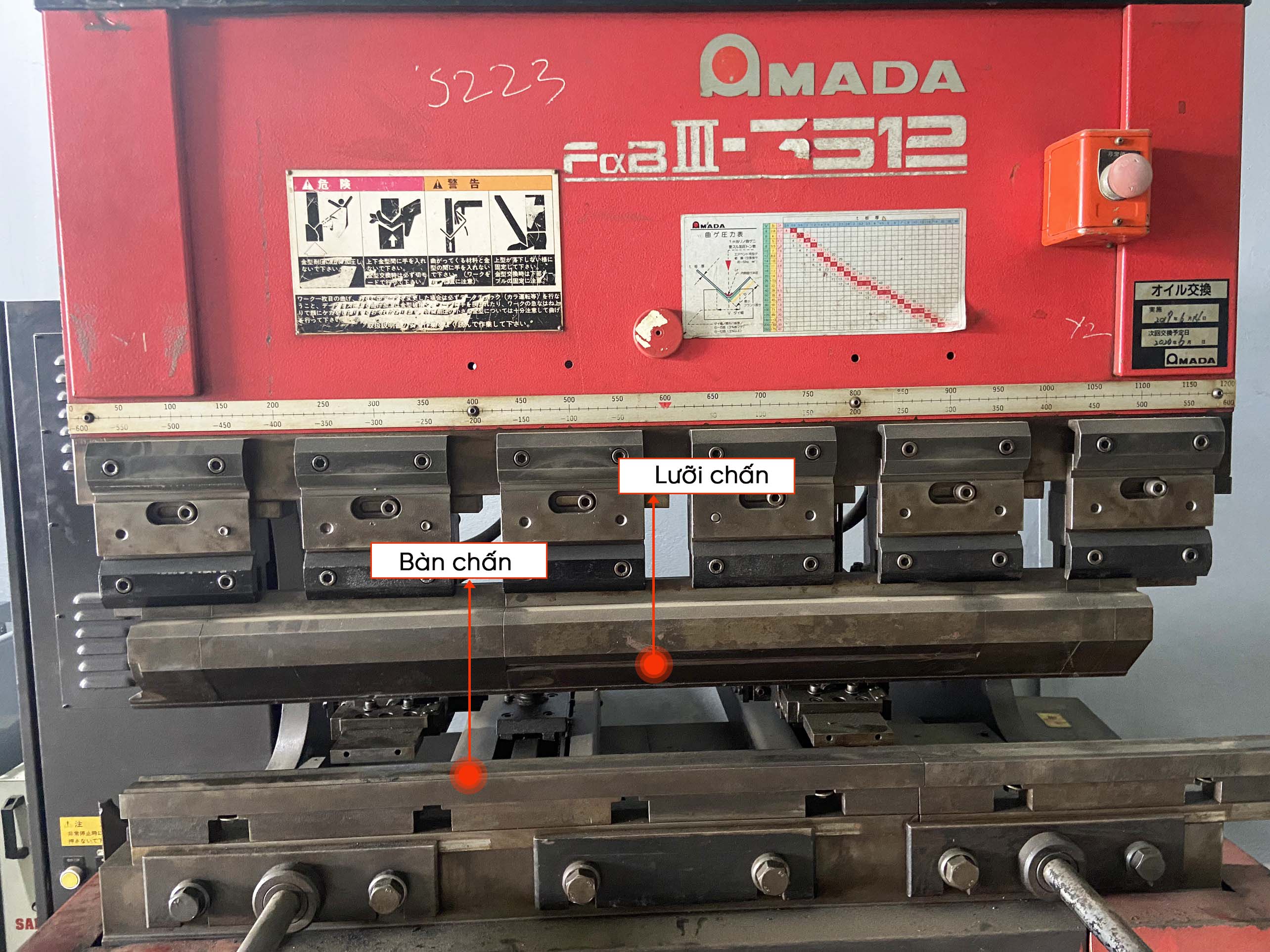

- Table - blade

- Transformers

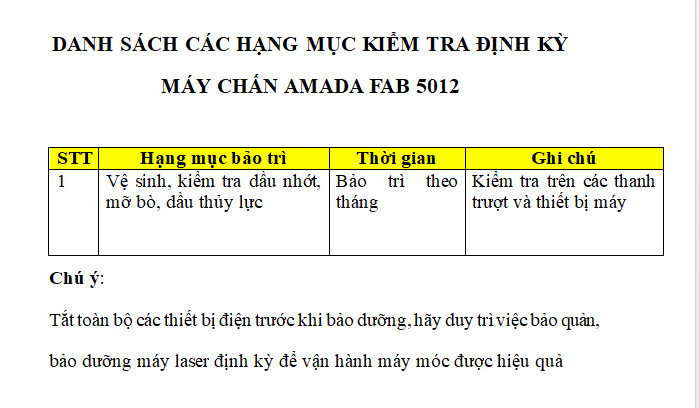

II. MACHINE MAINTENANCE PROCESS NEED TO KNOW

* It is necessary to follow the work that needs to be done every month to ensure stable operation of machines.

==> Details of the work to be done see the description below:

Vietnamese

Vietnamese

English

English