Introduce

Grinding is an indispensable stage in processing and cutting metal such as drilling, milling, planing, turning, and boring... When grinding, using a grinding stone, peel the excess metal layer on the part face, making the part of the final size achieve a high surface gloss.

Studer vertical grinder

The grinding wheel can peel a very thin layer of metal, so when grinding it can reach high accuracy (1/1mm). The grinding method can process the hardest metals including tempered steel.

Table of contents

Basic forms of grinding processing

Grinding is only used in cases where the processed product has a not-too-thick layer of metal that needs to be peeled away for the correct size with a smooth and glossy surface when no other processing method can be used.

The shape of the grinding parts is not the same, so there are also many types of grinding. The following are the basic forms of grinding machining:

- Grinding the outer surface of circular cylinders, i.e. grinding cylindrical details such as the outer surface of the transmission shaft, center axis, and spindle.

- Grinding the outside of round pyramids (taper), such as grinding the taper underpasses of the drill, the neck of the taper shafts, and the taper mandrels.

- Grinding detail holes, grinding inside

- Face grinding such as test table grinding has precision machining and polished sides, straight rulers, angle gauges, and other details.

Machining grinding methods

Grinding is a process of fabricating, or processing the surface of a material by removing the layer of unwanted material to create a smoother, more uniform, and more accurate surface. There are different grinding methods that depend on the intended use and properties of the material. Here are some common grinding methods:

-

Vertical Grinding: This method is often used to process long surfaces, such as shafts, pillars or swing arms of machines. Grinding takes place along the longitudinal of the material and is carried out using a longitudinal grinder.

Longitudinal grinding with a high-tech grinder

-

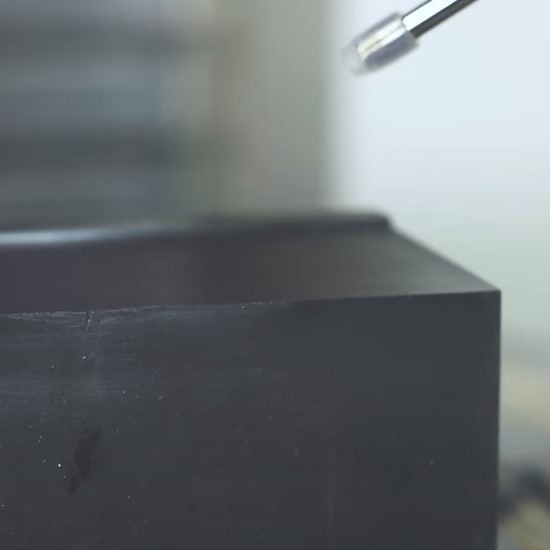

Deep Grinding: Deep Grinding is often used to remove large amounts of material and create deep-cutting surfaces. This is a precision machining process, often applied in the fabrication of industrial components that require high precision.

The automatic grinder is grinding into the iron billet

- Creep Feed Grinding: This method helps grind complex surfaces, uneven metal grain structures, or the need to remove materials quickly. The grinding process takes place at a slow speed, but great pressure between the grinding wheel and the material.

Finished workpiece after segmented grinding

Fractional grinding process

-

Rough grinding, Lapping: Rough grinding and fine grinding are often used to create precision and smooth surfaces. Rough grinding typically uses rotating grinding rods to process surfaces in round holes, while fine grinding uses flat surfaces for flat surface machining.

quá trình mài thô bằng máy cầm tay

Grinding crystals on the machine

Safety techniques when grinding machining

When performing the grinding process, safety is an important factor to ensure the protection of the person performing the work and avoid unwanted accidents. Here are some safety techniques that should be followed when grinding:

- Use protective equipment: Make sure to use adequate protective equipment, including helmets, goggles, masks, noise-canceled ears, and hard gloves to protect your eyes, ears, nose, mouth, and hands.

- Inspection and maintenance of the grinder: Before using the grinder, double-check the machine to ensure that it is working properly and safely. Regularly maintain the machine to maintain performance and avoid failure.

- Ensure a safe working position: Make sure that the working space around the grinder is clean, tidy, and free of excess materials, others should not stand too close when the machine is in operation.

- Wear worker protection: If possible, use additional protective equipment such as insulating materials or reduce contact between the performer and the machine.

- Grinding point control: Avoid overspeeding or over-stressing, which can cause an increased chance of an accident or grinding wheel breakage.

- Monitor the grinding process: Always concentrate and monitor the grinding process. Avoid distractions or lack of concentration when the machine is in operation.

- Limit grinding time: If you do grinding for a long time, take breaks between to avoid overload and fatigue.

- Choose the right grinding wheel and tool: Make sure to use the appropriate grinding wheel and tool for the material to be machined, ensuring the highest durability and efficiency.

- Do not use damaged or rusted grinding stones: Thoroughly inspect the grinding wheel before use and do not use grinding wheels that are damaged or have rust.

- Training and training: Ensure that employees have sufficient knowledge and skills to use grinding machines safely and effectively.

The article has generalized the basic grinding knowledge. Hope you have grasped the above content. Mechanical processing requires a large amount of knowledge and skills in the field. In addition, it is necessary to grasp and understand technical processing drawings to be able to visualize and apply to work. Vinahardware (VNH) with investment, innovation and constantly updating technology, we are proud to bring customers detailed and fast mechanical processing services at reasonable prices.

Tuan Anh-VNH

Vietnamese

Vietnamese

English

English