Air compressors, also known as inflators, are common equipment, including machines and mechanical systems that increase air pressure. Thereby helping the energy for the airflow increase, while compressing the air causes it to increase pressure and temperature. Air compressors are applied and contribute quite commonly in today's life.

=> Better understanding how to operate the AIR COMPRESSOR visit the following video link: https://youtu.be/AOk4jaO8I2w

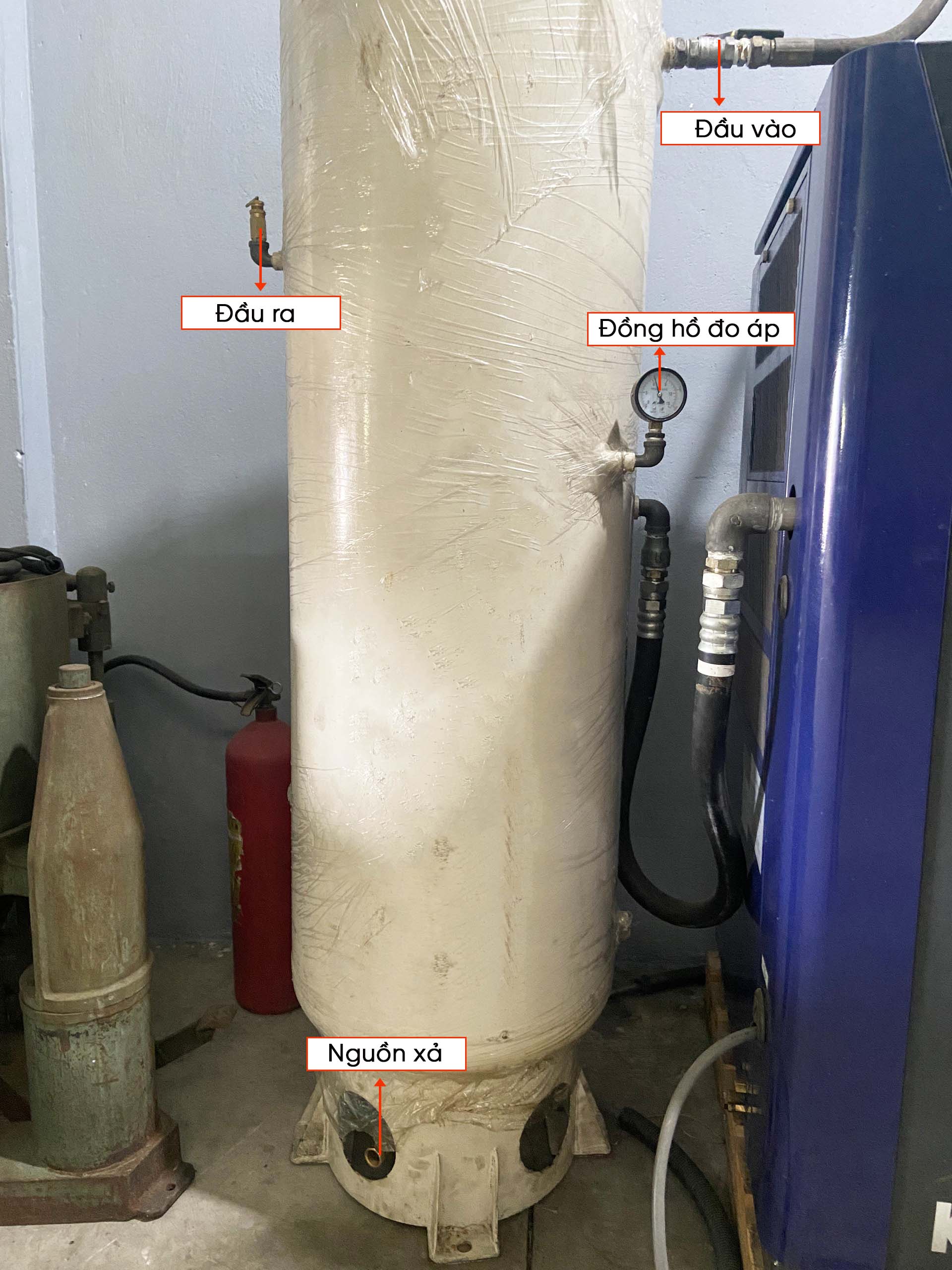

Air compressor structure

The air compressor is composed of the following main parts:

1. Air tank (accumulator)

- In the central compressed air system, this part has the function of storing compressed air and supplying it to the compressed air system when there is a sudden need for use. To help maintain the pressure in the system does not drop 1 suddenly. Avoid affecting the working process of equipment and machinery using compressed air.

- The air reservoir also has other functions such as a 1-part condenser of dirt, water and an air compressor. It feeds the system and lowers the temperature. Helps cool inlets for other equipment such as air dryers, air purifiers and other compressors.

- Air tanks are divided into several types: High pressure gas tanks and low pressure gas tanks, gas tanks use stainless steel.

2. Gas treatment equipment

- The compressed air generated from air compressors contains a lot of different contaminants depending on the degree. Dirt can include water vapor, dirt in the air, residues of lubricant. Compressed air will cause corrosion, rust in the pipe and molecules of the control system. Therefore, it is necessary to treat compressed air by the following methods:

- Drying method: To remove most of the water inside.

- Drying by absorption. That is, the drying agents will absorb the water in the humid air. The device consists of 2 vessels: the jar will dry and absorb moisture. The other vessel will reproduce the absorbing capacity of the drying agent.

- Air drying: Compressed air passes through the heat exchanger by reversing the compressed air flow in the tubes. The cooling process will be done and the dew stagnant temperature here is 20-28 degrees. Thus, the amount of water vapor in the compressed air stream will be condensed. After being removed from the compressed air stream, the waterhead contaminants will separate by the condensate drain valve.

- Coarse air filtration: Use a filter element to filter coarse dust in combination with a compressor.

- Fine air filtration: Removes all impurities, including those of very small size.

3. Other auxiliary equipment

- Automatic discharge unit: in locations where the compressed air system is prone to condensation, the discharge unit will be installed in the compressed air supply pipeline system. Can be installed at a communal location or location at the request of the user.

- Pressure gauge: Make it easier to monitor and operate.

- Compressed air preheater: Helps to pre-cool the compressed air of the compressor before supplying it to compressed air treatment equipment such as air dryer, coarse air filter, fine air purifier.

- How to operate the machine

- Air tanks

- Transformers

Vietnamese

Vietnamese

English

English