1500mm Full Folding Bed Lift Mechanism – Model 1802.1.91500

- Status: Out of stock

- Vendor: Vinahardware

🛏️ Full Folding Bed Lift Mechanism 1500mm – Model 1802.1.91500

Brand: Vinahardware

Origin: Vietnam

Product Type: Bed Frame Lifting Hardware (Gas spring not included – choose separately based on bed weight)

🔧 PRODUCT SPECIFICATIONS

-

Material: High-tensile flexible steel plate (thickness: 3mm, 4mm, 5mm)

-

Finish: Black powder-coated surface for anti-rust and durability

-

Structure: Heavy-duty laser-cut frame with CNC-machined joints

-

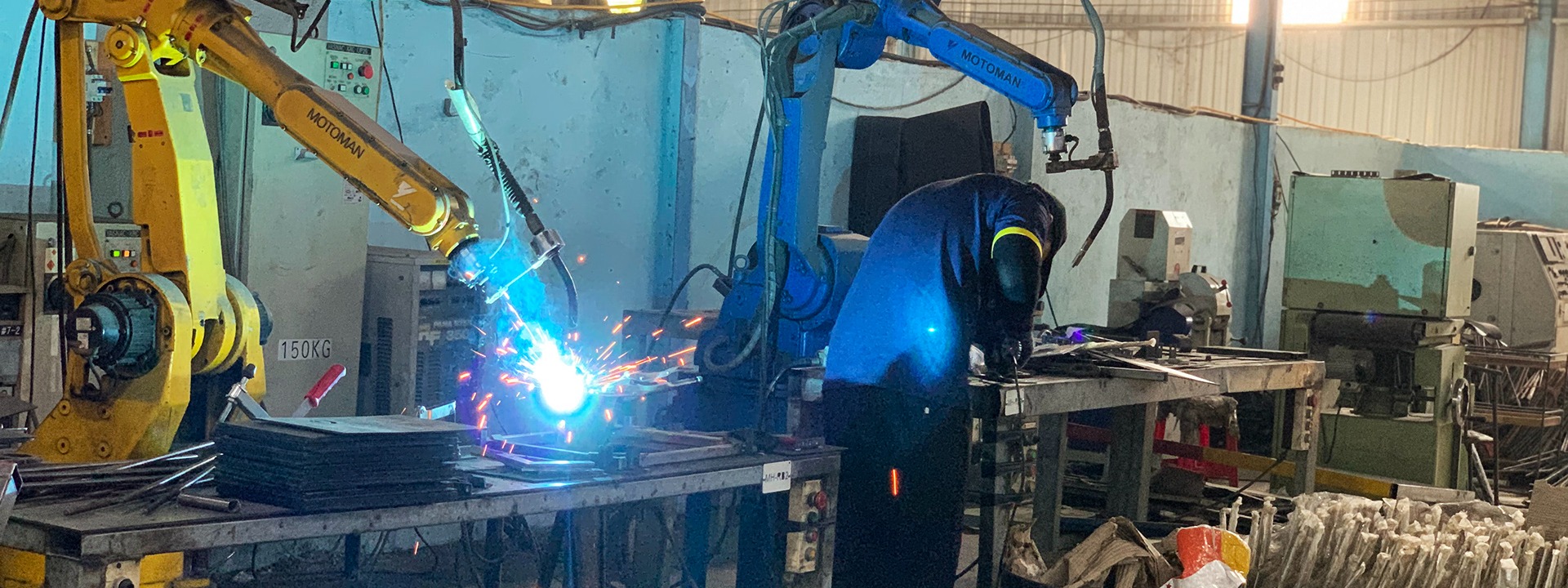

Welding: Automated robotic welding ensures consistent and precise joint strength

-

Installation: Pre-drilled mounting slots for easy bed frame integration

-

Compatibility: Designed for full-lift bed frames with a width of 1500mm

-

Gas spring support: Not included – user can select appropriate gas struts (pistons) based on required lift force

⚙️ FEATURES & ADVANTAGES

-

Strong structural integrity with CNC-machined precision parts

-

Engineered to support large and heavy bed bases with minimal manual effort

-

Customizable lifting force by selecting compatible gas pistons

-

Robust, quiet operation ideal for modern smart home furniture solutions

-

Anti-scratch packaging and full QC inspection before delivery

-

Powder-coated for long-lasting finish, even in humid environments

🏠 APPLICATIONS

-

Suitable for smart bed furniture, Murphy beds, wall-beds, and modular lift-up beds

-

Trusted by furniture factories, interior designers, and project contractors

📦 PACKAGING & DELIVERY

-

Each set includes:

-

1 left and 1 right bed lift mechanism (without gas pistons)

-

Screws and hardware accessories

-

-

Packaging: Anti-scratch wrap + durable carton box

-

Production lead time: Approx. 10–13 working days after order confirmation (MOQ: 1000 sets)

- Easy to install and use.

- Convenient for users.

- Save bedroom space.

- Tidy and neat.

🏭 PRODUCTION PROFILE – VINAHARDWARE

This product is manufactured at Vinahardware Manufacturing & Export JSC (VNH) under a strict and professional production process, ensuring durability, consistency, and technical precision.

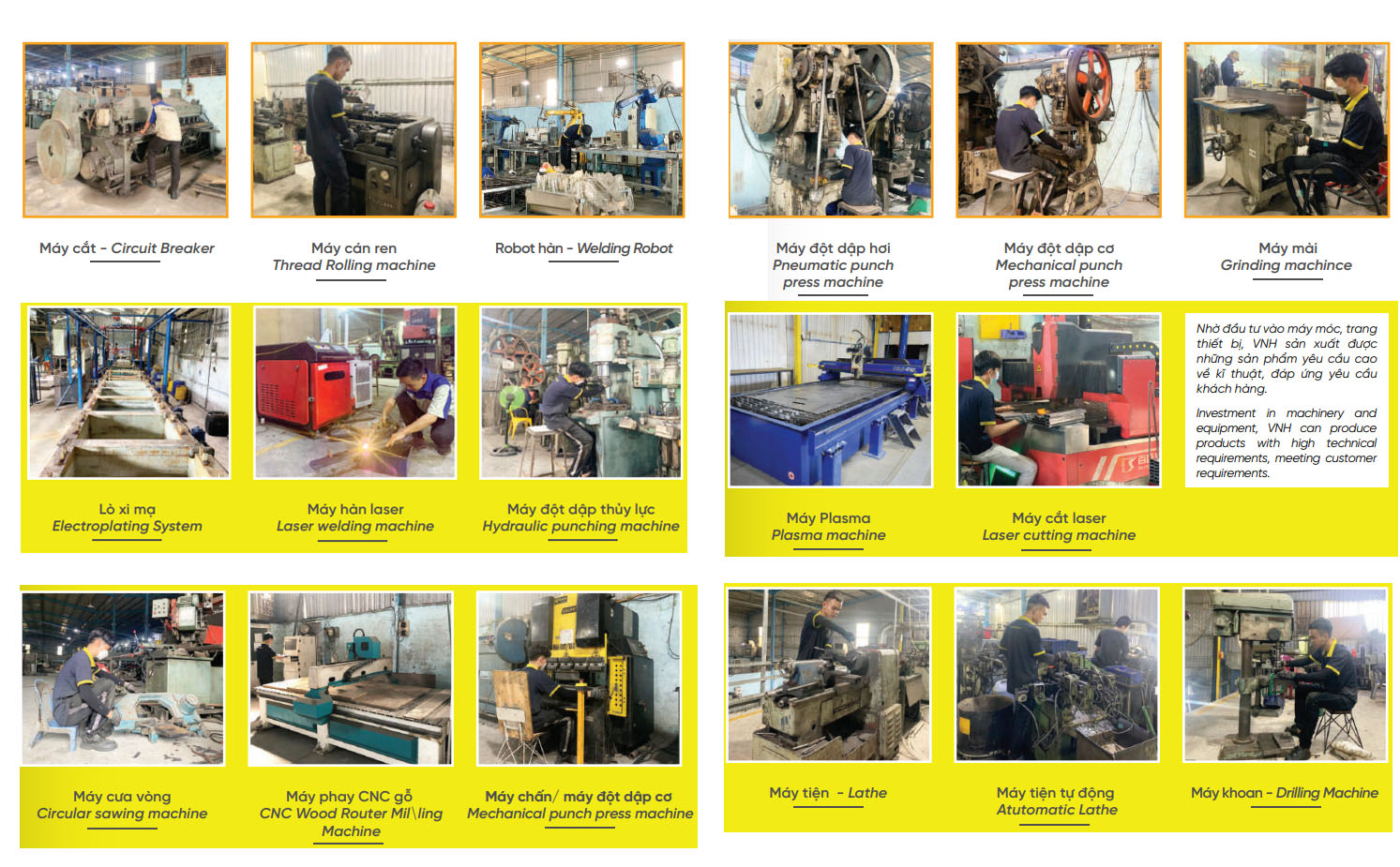

🔧 Standard Production Workflow:

-

Laser cutting of steel plates – High precision according to technical drawings

-

Stamping and CNC bending – Accurate shaping of structural parts

-

Lathe machining for shafts & fasteners – Precise threading and fit

-

Robotic welding – Clean, strong welds with consistent quality

-

Surface cleaning and burr removal – For perfect finishing before coating

-

Powder coating (Black) – Uniform anti-rust layer for long-term durability

-

Manual assembly & technical testing – Ensures proper functionality

📋 PROFESSIONAL QC CHECKLIST

All units are thoroughly inspected before packing and shipping, following Vinahardware’s internal quality standards:

| Inspection Item | Requirement Description | Status |

|---|---|---|

| 1. Brand Logo | Clearly engraved/stamped Vinahardware logo | ✅ |

| 2. Material Confirmation | High-grade steel, correct thickness as per design | ✅ |

| 3. Color Consistency | Even, matte black powder coating | ✅ |

| 4. Welding Quality | Clean, solid robotic welds, no splatter or cracks | ✅ |

| 5. Dimensional Accuracy | Within specified tolerance of technical drawings | ✅ |

| 6. Surface Condition | No scratches, dents, or rust | ✅ |

| 7. Mechanical Strength | Load-bearing capacity tested and approved | ✅ |

| 8. Accessory Completeness | All parts included and well-packed | ✅ |

| 9. Packaging & Labeling | Anti-scratch wrap + product code and labels | ✅ |

| 10. Functional Testing | Smooth operation, full movement range verified | ✅ |

✅ VINAHARDWARE QUALITY COMMITMENT

-

All products manufactured per custom order and technical specs

-

100% functional inspection before packaging

-

Technical documents and production certificates available upon request

Technical drawing of Vinahardware bed lift hand

See more products of bed lifters

https://www.youtube.com/watch?v=syPCrVaM4QA

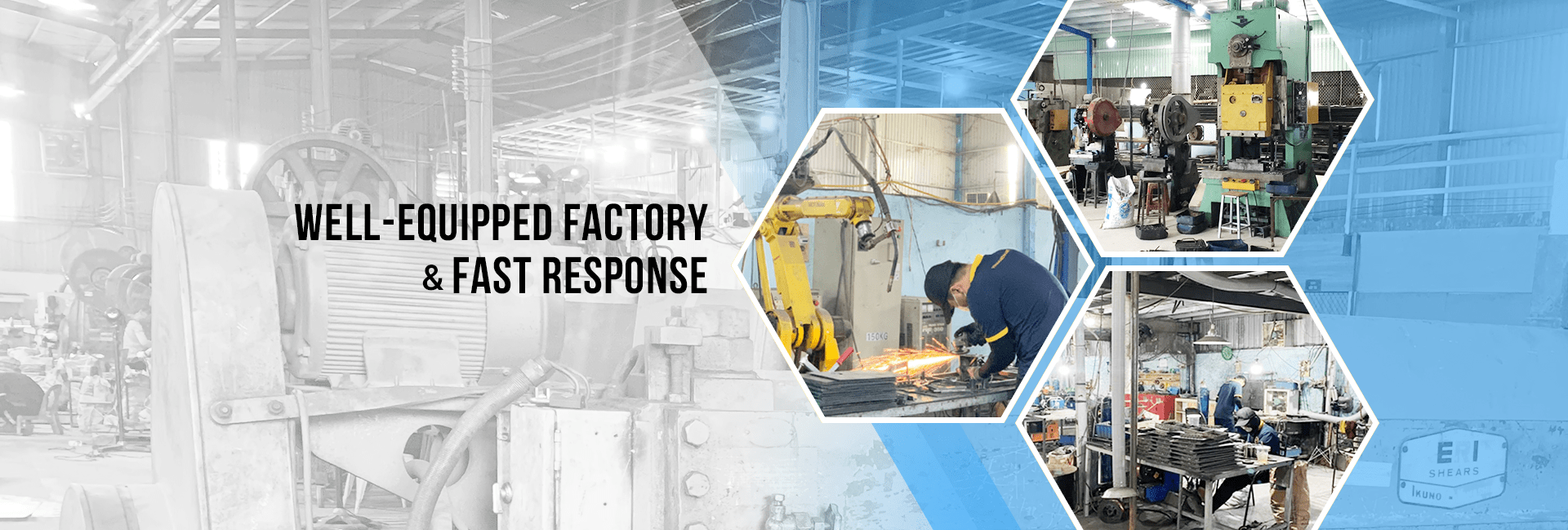

VINAHARDWARE (VNH) MECHANICAL PROCESSING TECHNOLOGY MACHINERY

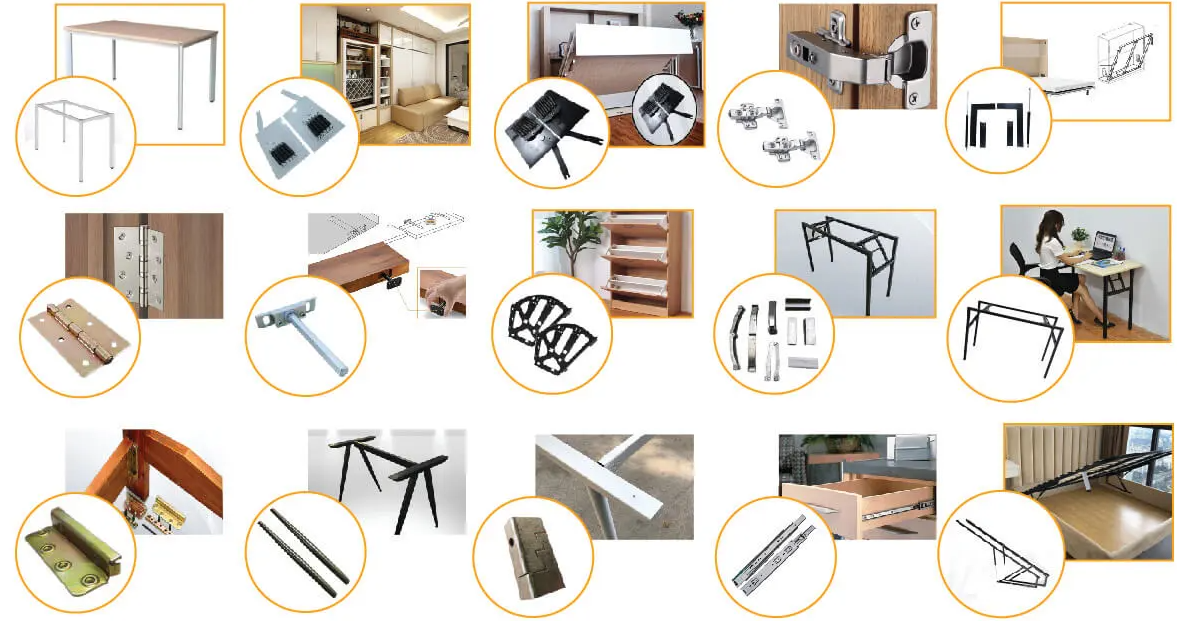

RELATED PRODUCTS VINAHARDWARE (VNH)

Also directly manufactures table and chair frames, iron brackets, sliding rails, hinges, smart accessories, etc. We participate in social housing projects and modular housing. Our products are not only distributed to domestic customers but also well-received worldwide, including Australia, New Zealand, the United States, etc.

👉🏻See all products with vinahardware's Catalogue

Australian Customers Visit VINAHARDWARE

VINAHARDWARE AT VIETBUILD INTERNATIONAL EXHIBITION AND VIFA EXPO INTERNATIONAL EXHIBITION

The products have been well received and highly praised by both domestic and international customers for their quality and meticulous attention to detail in every aspect of the products.

WHY CHOOSE VINAHARDWARE (VNH)

Q & A - QUESTIONG AND ANSWER WITH VINAHARDWARE (VNH)

1. Does VINAHARDWARE provide custom processing?

Vinahardware (VNH) offers custom processing, OEM, and according to customer requirements. Established since 2012, with over 10 years of experience in mechanical processing, Vinahardware (VNH) is confident in delivering high-quality products that meet customer expectations, ranging from simple to complex.

2. Does VINAHARDWARE (VNH) require specific documents from customers for processing?

With just one of the following three pieces of data, Vinahardware can provide pricing information and consultation to customers. The quotation process becomes more convenient if customers provide more specific and detailed requirements.

- Product drawings

- Product images

- Physical samples

Vinahardware (VNH) looks forward to the opportunity to cooperate with you!

Vietnamese

Vietnamese

English

English