Manufacturing process table legs SP2208358

- Status: Out of stock

- Vendor: Vinahardware

Manufacturing process table legs SP2208358

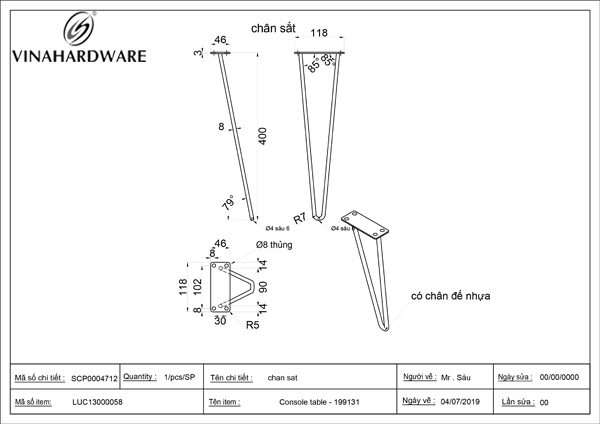

See the detailed drawing board >>> Here

I. Customers request products:

- Compare samples before machining.

- Choose a supplier of beautiful white iron, if it is not good, do not do.

- The leg frame is 400mm high, using 8mm iron.

- Natural color of iron, surface treatment without rust.

- Anti-rust glue coating treatment.

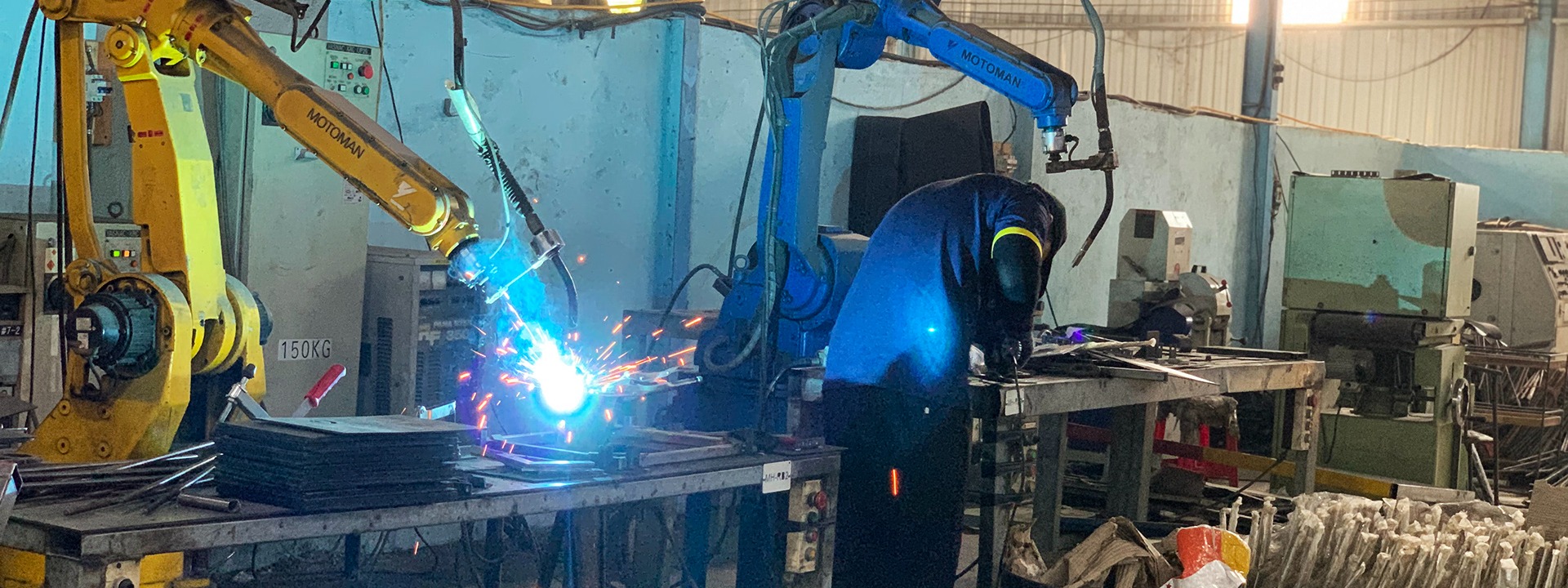

- Requires beautiful, strong welds.

- The surface of the material is flat, with rough claws to ensure classicism.

Check the exact tilt angle of 79 degrees according to the drawing board link (with a 1-degree shift).

II. Foot frame processing process:

1. Check the data entry process: Solid round and flat surfaces are beautiful if the material is not returned to the supplier.

2. Use a machine to chop and cut materials as required.

3. Processing iron plastering according to size.

4. Use the gesture to pay attention to the angle of inclination in accordance with the customer drawing (this part is careful and accurate): gesture for an angle of inclination of 79 degrees (or borrow gestures from the customer for comparison).

Surface on grinding clean

The position of welding pins

Machine for bending leg frames

III. Product color processing:

- Clean treatment of PC material surfaces.

- Sanding: pay attention to swiping for a natural surface. The site of rust wiped clean.

- Glossy coating.

IV. Product inspection before delivery:

You check:

1. Check the correct tilt angle of 80 degrees? If reprocessing has not been achieved.

2. Check the surface to ensure no rust? If reprocessed.

3. Is weld inspection beautiful?

4. Check 4mm hole gouging, 6mm deep plastic button?

5. Pack and transfer to warehouse carefully.

Detailed drawings of table leg frames

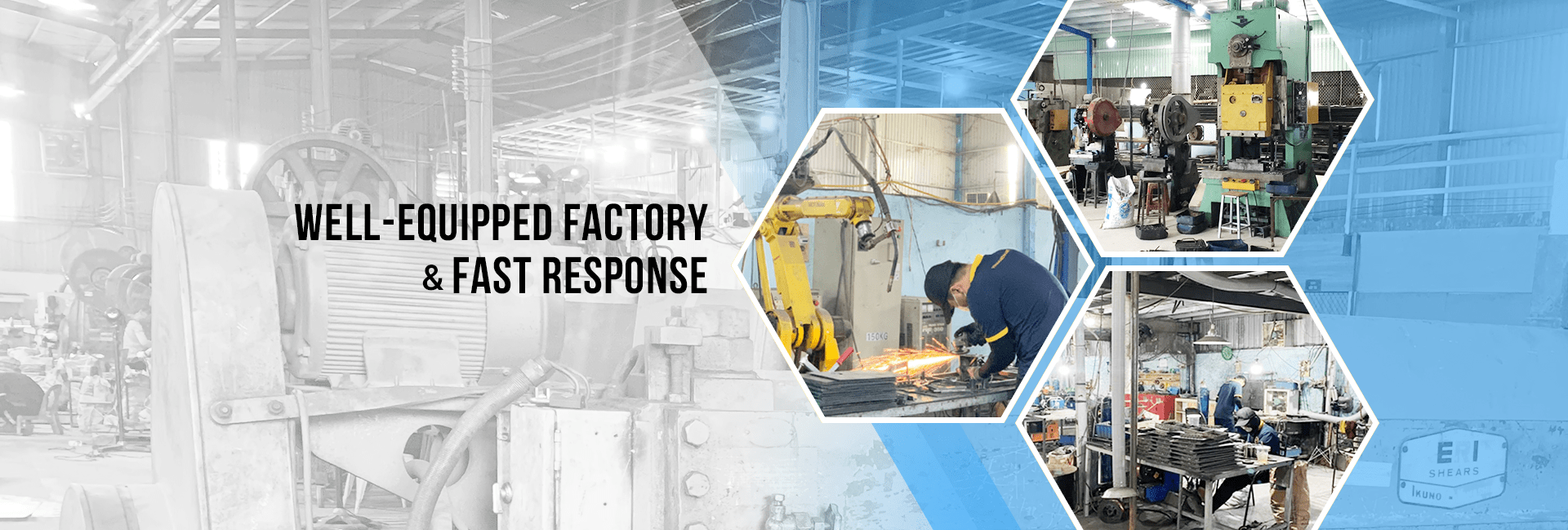

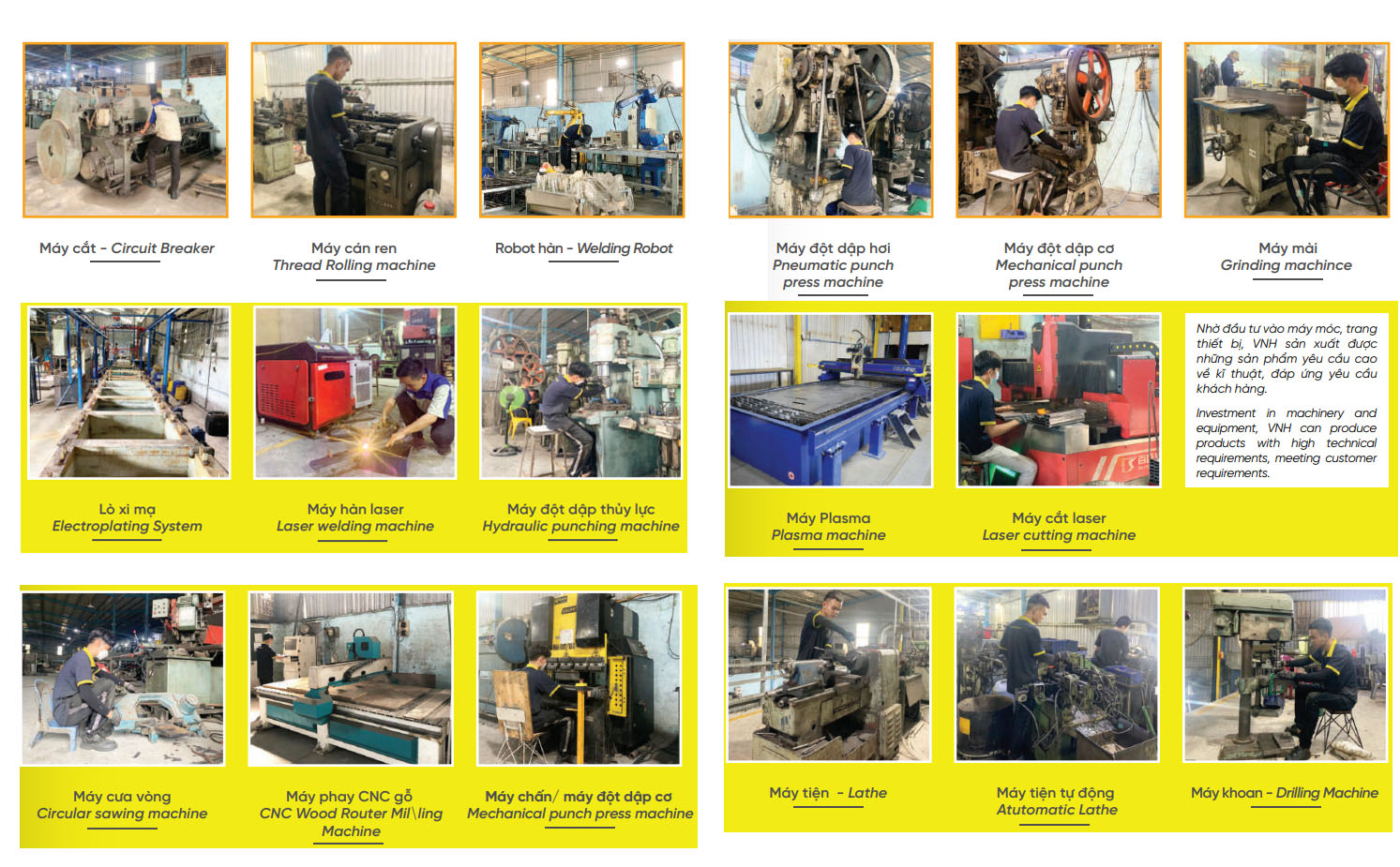

VINAHARDWARE (VNH) MECHANICAL PROCESSING TECHNOLOGY MACHINERY

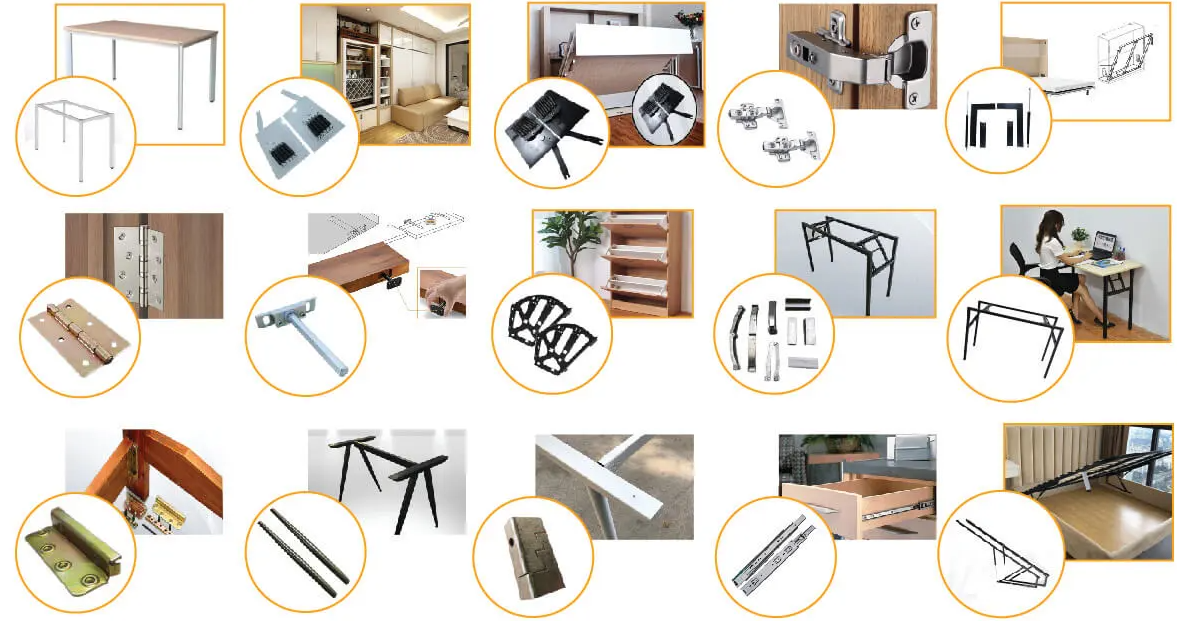

RELATED PRODUCTS VINAHARDWARE (VNH)

Also directly manufactures table and chair frames, iron brackets, sliding rails, hinges, smart accessories, etc. We participate in social housing projects and modular housing. Our products are not only distributed to domestic customers but also well-received worldwide, including Australia, New Zealand, the United States, etc.

👉🏻See all products with vinahardware's Catalogue

Australian Customers Visit VINAHARDWARE

VINAHARDWARE AT VIETBUILD INTERNATIONAL EXHIBITION AND VIFA EXPO INTERNATIONAL EXHIBITION

The products have been well received and highly praised by both domestic and international customers for their quality and meticulous attention to detail in every aspect of the products.

WHY CHOOSE VINAHARDWARE (VNH)

Q & A - QUESTION AND ANSWER WITH VINAHARDWARE (VNH)

1. Does VINAHARDWARE provide custom processing?

Vinahardware (VNH) offers custom processing, OEM, and according to customer requirements. Established since 2012, with over 10 years of experience in mechanical processing, Vinahardware (VNH) is confident in delivering high-quality products that meet customer expectations, ranging from simple to complex.

2. Does VINAHARDWARE (VNH) require specific documents from customers for processing?

With just one of the following three pieces of data, Vinahardware can provide pricing information and consultation to customers. The quotation process becomes more convenient if customers provide more specific and detailed requirements.

- Product Drawings

- Product images

- Physical samples

Vinahardware (VNH) looks forward to the opportunity to cooperate with you!

Vietnamese

Vietnamese

English

English